Sado Seimitsu, Inc.

Sado Seimitsu, Inc.

Ti alloy, Ni-base alloy, general stainless steels, aluminum alloy, copper alloy, tungsten alloy, Kovar, etc.

Jet engine parts, landing gear parts, sensor parts, actuator parts, interior parts, airframe parts

・ISO9001

・JIS Q9100

・Eco Action 21

Medical equipment, medical instruments, aircraft parts, fuel cells, bearings, semiconductors, OA equipment, etc.

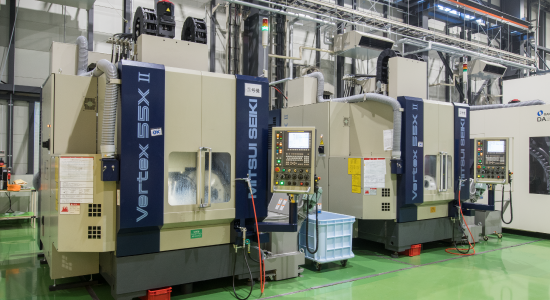

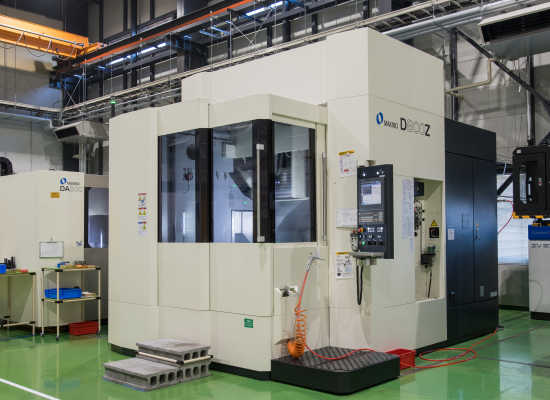

Simultaneous five axis MC

Simultaneous five axis MC

CNC composite lathe

CNC composite lathe

CNC composite lathe

CNC composite lathe

Simultaneous five axis MC

Simultaneous five axis MC

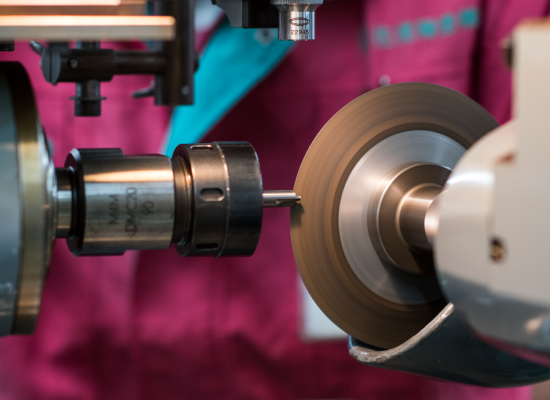

Cylindrical grinding machine

Cylindrical grinding machine

NC automatic lathe

NC automatic lathe

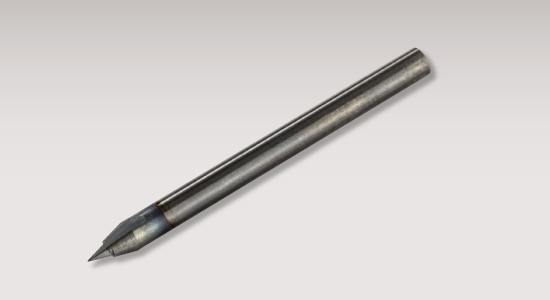

Tools grinding board

Tools grinding board

CAM operator

CAM operator

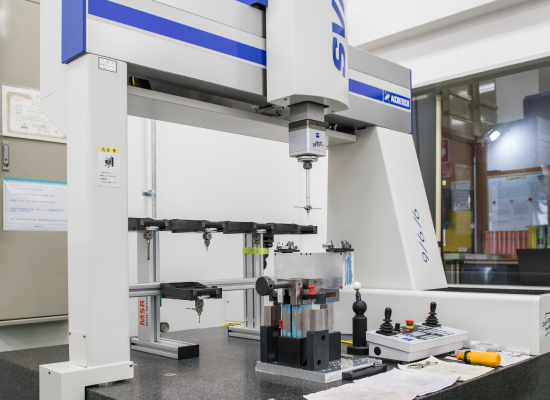

CNC three-dimensional measuring machine

CNC three-dimensional measuring machine

We supply precision machined parts to various fields including medical, aviation, and energy.

We provide competitive parts to our customers by taking advantage of production management using IT, cultivating national certified and skilled workers, in-house manufacturing of cutting tools, and introducing the latest processing technology.